Ferro silicon 75 is a common metallurgical material with 75% silicon content, which is a common raw material used in steel making. The raw materials used to produce ferro silicon 75 are mainly coke, steel chips and quartzite, which are produced by heating and smelting in electric furnaces.

Ferro silicon is an important alloy, which can remove oxygen from the steel in iron and steel production and increase the final quality of the steel. Ferrosilicon is also the basis of pre-alloys for the manufacture such as fesimg for the modification ofmelted malleable cast irons. Ferrosilicon is a type of alloy, silver-gray, with blocky, spherical, granular and powdery shapes.Since silicon and oxygen are easily combined to produce silicon dioxide, ferrosilicon is used as a deoxidizer in steelmaking production. When the silicon in the ferro silicon combines with oxygen, a large amount of heat is released due to the formation of SiO2, which is also beneficial to increase the temperature of the molten steel while deoxidizing. In the steelmaking industry, about 3-5kg of 75% ferrosilicon is consumed to produce one ton of steel.

Ferrosilicon can also be used as alloying element additives, widely used in low-alloy structural steel, spring steel, bearing steel, heat-resistant steel and electrical silicon steel.

It is an essential deoxidizer in the steelmaking industry. In the steelmaking industry, ferrosilicon is used for precipitation deoxidation and diffusion deoxidation. It is also used as an alloying agent in steelmaking. The addition of a certain amount of silicon can significantly improve the intensity, hardness and elasticity of steel, improve the permeability of steel, and reduce the magnetic hysteresis loss of transformer steel. The content of silicon is 0.15%-0.35% in general steel, 0.40%-1.75% in structural steel, 0.30%-1.80% in tool steel, 0.40%-2.80% in spring steel, 3.40%-4.00% in stainless acid-resistant steel, 1.00%-3.00% in the heat-resistant steel, and 2%-3% or more in the silicon steel.

High-silicon ferrosilicon or siliceous alloys are used as reducing agents for the production of low-carbon ferroalloys. The addition of ferrosilicon in cast iron can be used as a nucleating agent for nodular cast iron, preventing the formation of carbide, promoting the precipitation and spheroidization of graphite, and improving the performance of cast iron.

In addition, ferrosilicon powder can be used as a suspended phase in the mineral dressing industry, and used as a coating for the welding rod in the welding rod manufacturing industry. High silicon ferrosilicon can be used to produce the semiconductor pure silicon in the electrical industry, and used to prepare silicone and other materials in the chemical industry.

Ferrosilicon is a kind of ferroalloy that is composed produced by reduction of silica or sand with coke in the presenceof iron. Typical sources of iron are scrap iron or milscale. Ferrosilicons with silicon content up to about 15% are madein blast furnaces lined with acid fire bricks. Ferrosilicons with higher silicon content are made in electric arc furnacesThe usual formulations on the market are ferrosilicons with 60-75%silicon, The remainder is iron. with about 2%consisting of other elements like aluminium and calcium. An overabundance of silica is used to prevent formationof silicon carbide.

Ferrosilicon is widely used in the production in steelmaking, casting and other industries.

Ferro silicon is widely used as deoxidizer and alloy additive in steelmaking.

Ferro silicon powder emits a lot of heat in steel making production, and is used as a heating agent for steel ingot caps to improve the recovery rate and quality of steel ingots.

Ferro silicon can be used as inoculant and nodulizer for cast iron

High silicon content ferrosilicon alloy is a commonly used reducing agent in the production of low-carbon ferroalloys in the ferroalloy industry.

Ferro silicon powder or atomized ferrosilicon powder can be used as coating for welding rod production.

Ferro silicon can be used for high-temperature smelting of magnesium metal. 1 ton of metallic magnesium needs to consume about 1.2 tons of ferrosilicon.

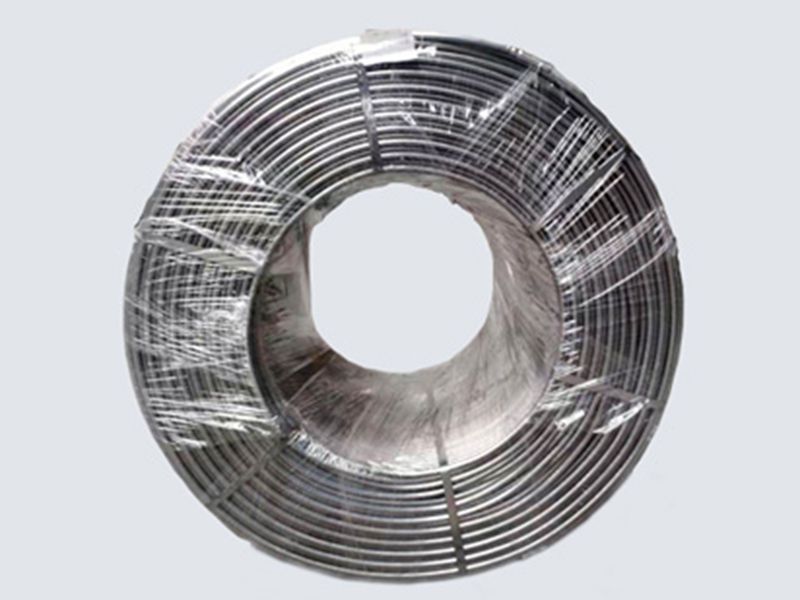

1-ton or 0.5-ton bags are used for natural blocks; 25kg woven bags with moisture-proof inner membrane or plus 1-ton or 0.5-ton outer bags/plastic woven bags are used for power; packages required by customers are also supported.

| Type | Element content (not greater than) | |||||||

| %Si(max) | Al(max) | Ca(max) | Mn(max) | %Cr(max) | P(max) | S(max) | %C(max) | |

| FeSi90Al1.5 | 87.0-95.0 | 1.5 | 1.5 | 0.4 | 0.2 | 0.040 | 0.020 | 0.20 |

| FeSi90Al3.0 | 87.0-95.0 | 3.0 | 1.5 | 0.4 | 0.2 | 0.040 | 0.020 | 0.20 |

| FeSi75Al0.5-A | 74.0-80.0 | 0.5 | 1.0 | 0.4 | 0.3 | 0.035 | 0.020 | 0.10 |

| FeSi75Al0.5-B | 72.0-80.0 | 0.5 | 1.0 | 0.5 | 0.5 | 0.040 | 0.020 | 0.20 |

| FeSi75Al1.0-A | 74.0-80.0 | 1.0 | 1.0 | 0.4 | 0.3 | 0.035 | 0.020 | 0.10 |

| FeSi75Al1.0-B | 72.0-80.0 | 1.0 | 1.0 | 0.5 | 0.5 | 0.040 | 0.020 | 0.20 |

| FeSi75Al1.5-A | 74.0-80.0 | 1.5 | 1.0 | 0.4 | 0.3 | 0.035 | 0.020 | 0.10 |

| FeSi75Al1.5-B | 72.0-80.0 | 1.5 | 1.0 | 0.5 | 0.5 | 0.040 | 0.020 | 0.20 |

| FeSi75Al2.0-A | 74.0-80.0 | 2.0 | 1.0 | 0.4 | 0.3 | 0.035 | 0.020 | 0.10 |

| FeSi75Al2.0-B | 72.0-80.0 | 2.0 | 0.5 | 0.5 | 0.040 | 0.020 | 0.20 | |

| FeSi75-A | 74.0-80.0 | 0.4 | 0.3 | 0.035 | 0.020 | 0.10 | ||

| FeSi75-B | 72.0-80.0 | 0.5 | 0.5 | 0.040 | 0.020 | 0.20 | ||

| FeSi65 | 65.0-72.0 | 0.6 | 0.5 | 0.040 | 0.020 | |||

| FeSi45 | 40.0-47.0 | 0.7 | 0.5 | 0.040 | 0.020 | |||